We are always looking for ways to improve our efficiency and productivity to better serve our customers. Over the years we have improved many systems such as upgrading pumps to reduce fill time. In 2012 we purchased our first Turbine powered aircraft that proved to be a true work horse, in 2013 we converted our two Air Tractors to Turbine which again improved efficiency, reliability and productivity.

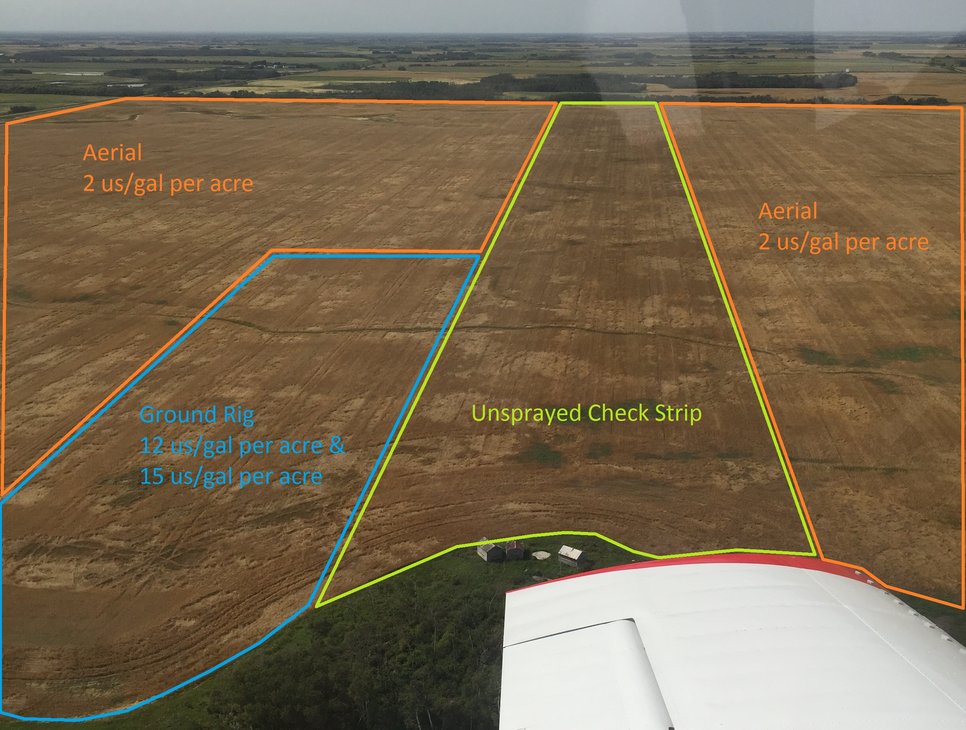

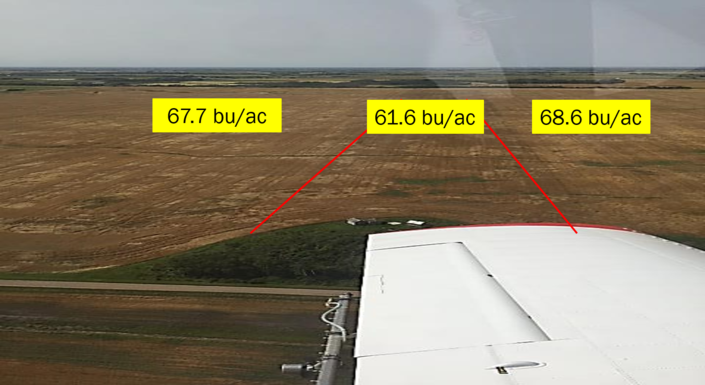

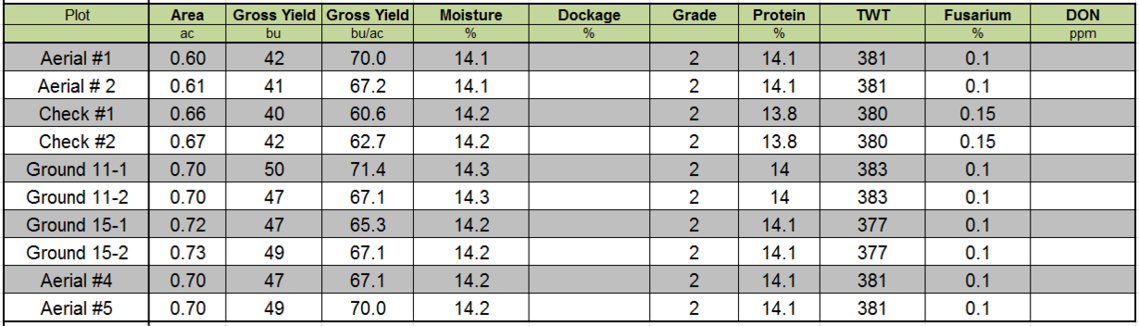

One area of spraying whether with an aircraft or ground rig that can be changed to improve productivity and efficiency is reducing water volumes. This has been a debate amongst growers, manufacturers and agronomists that has been ongoing forever! The mindset has always been that more water will ensure better coverage and therefore better results however we have proven that is not always correct. The industries solution has been to build larger sprayers with enormous tanks to try an improve efficiency. What about reducing water volume and focus on proper calibration and set up of your sprayer. Take a 1200 us gallon ground rig making a 10 us/gal per acre application of fungicide. On a full quarter section (160 acres) you still need to stop and fill once before completing the field. If you reduce the water to 7.5 us/gal per acre or less think of the efficiency and productivity gains per hour. Now it is not as simple as just cutting back the water, careful consideration has to be given to ensure the sprayer and nozzles are set up properly and capable of creating the correct droplet spectrum to ensure proper coverage. It is not the amount of water you put through your sprayer that ensures proper coverage but the selection of nozzle and sprayer set up that creates the correct droplet spectrum for the product being applied.

We have spent a great amount of time and effort on researching different aerial application nozzles, including bringing in aircraft calibration specialists that have worked with some of the largest farms in the world to improve efficiency and productivity. These specialists convey the same message that more water is not the answer, but a properly calibrated sprayer with lower water will do the same and in most cases provide better results and improved yields. Our research has shown that rotary atomizers are one of the most effective nozzles available for aerial application. The nozzles ability to control droplet size over a broad range make them very effective at producing a uniform pattern that ensures proper coverage. Through numerous calibration and product trials using our ASC A10 rotary atomizers we have proven that our systems are most effective in providing efficient and adequate coverage at 2 us/gal per acre or less.

Above: Thrush Calibration flight at 1.5 us/gal per acre, note the uniform pattern and amount of droplets created by the ASC A10 Rotary Atomoizers.